Commercial

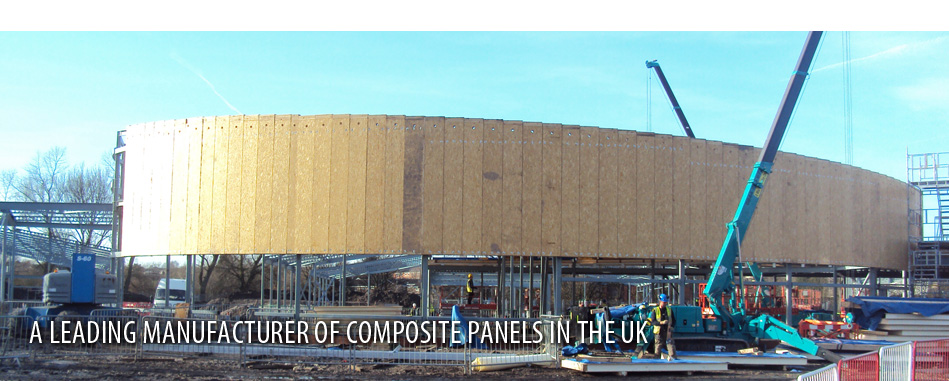

SIP Building Systems Ltd have demonstrated that SIP panels can be used in a large range of commercial projects such as hotels, schools, super markets & universities; with the speed of construction and the fact that the weather conditions do not really disrupt the building process, SIPS have proved to be a major success in the winter months. One great advantage of using SIPS in commercial projects is that many external products can be hung on the outside face of the SIP panel such as: Aluminium Rainscreens, Terracotta Tile, Render, Brick, Timber, Granite Tiles etc...

SIP Building Systems Ltd have demonstrated that SIP panels can be used in a large range of commercial projects such as hotels, schools, super markets & universities; with the speed of construction and the fact that the weather conditions do not really disrupt the building process, SIPS have proved to be a major success in the winter months. One great advantage of using SIPS in commercial projects is that many external products can be hung on the outside face of the SIP panel such as: Aluminium Rainscreens, Terracotta Tile, Render, Brick, Timber, Granite Tiles etc...

SIP panels on commercial projects can either be hung inside or outside the slab to compete against other products such as composite and SFS systems; SBS can produce lengths up to 6250mm with thickness of panel varying from 75mm – 250mm.

SIP panels on commercial projects can either be hung inside or outside the slab to compete against other products such as composite and SFS systems; SBS can produce lengths up to 6250mm with thickness of panel varying from 75mm – 250mm.

SIP Building Systems Ltd work alongside some of the largest architects, structural engineers, main contractors and cladding contractors to deliver projects all over the UK.

More and more Developers, Public Sector and Local Authorities are keen to build with SIPS due to the ever increasing energy bills as SIPS create a very air tight building which lead to lower running costs. Large format panels are becoming more popular with Main Contractors as this reduces their build time which ultimately saves the end

user money on their build cost.

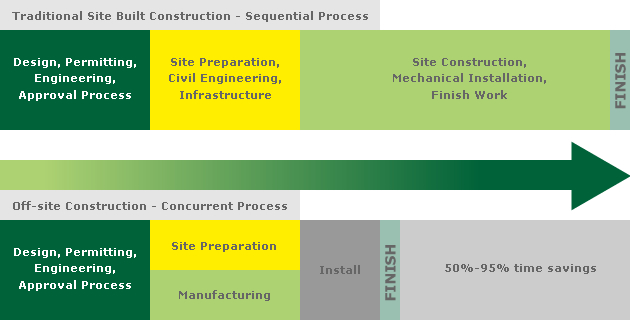

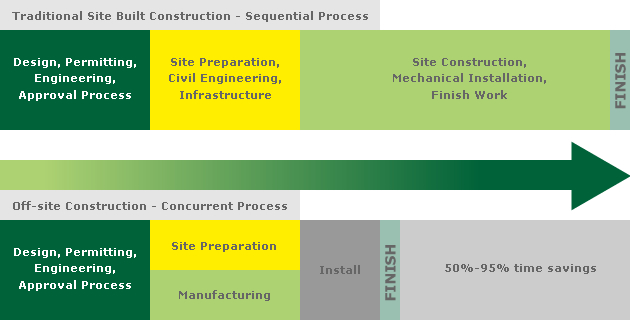

Offsite construction is already widely used in the US, Japan and Germany and offers many advantages over site-based construction:

- Manufacturing and installation efficiencies and cost savings.

- Concurrent site and building construction.

- A stable and abundant supply of labour.

- Reduced weather delays and weather damage rework.

- Less site disruption, construction traffic and waste.

- Buildings are available to occupy much sooner, reducing costs and generating revenue sooner.

- Construction time is reduced dramatically; 50-95% of the building can be built in our factory and supplied as single panels, full wall elevations or modular units depending upon access, saving both time and money.

- The offsite manufacturing process of our unique building system moves wall construction from the jobsite to a highly controlled manufacturing environment, significantly shortening the build cycle and improving quality.

SIP Building Systems Ltd have demonstrated that SIP panels can be used in a large range of commercial projects such as hotels, schools, super markets & universities; with the speed of construction and the fact that the weather conditions do not really disrupt the building process, SIPS have proved to be a major success in the winter months. One great advantage of using SIPS in commercial projects is that many external products can be hung on the outside face of the SIP panel such as: Aluminium Rainscreens, Terracotta Tile, Render, Brick, Timber, Granite Tiles etc...

SIP Building Systems Ltd have demonstrated that SIP panels can be used in a large range of commercial projects such as hotels, schools, super markets & universities; with the speed of construction and the fact that the weather conditions do not really disrupt the building process, SIPS have proved to be a major success in the winter months. One great advantage of using SIPS in commercial projects is that many external products can be hung on the outside face of the SIP panel such as: Aluminium Rainscreens, Terracotta Tile, Render, Brick, Timber, Granite Tiles etc...  SIP panels on commercial projects can either be hung inside or outside the slab to compete against other products such as composite and SFS systems; SBS can produce lengths up to 6250mm with thickness of panel varying from 75mm – 250mm.

SIP panels on commercial projects can either be hung inside or outside the slab to compete against other products such as composite and SFS systems; SBS can produce lengths up to 6250mm with thickness of panel varying from 75mm – 250mm.